Contact Number : 029-83891808

Universal silicon carbide rod is a non-metallic electric heating element made mainly from high-purity green silicon carbide through high-temperature recrystallization process. Long term application in various electric furnaces, mature technology, and stable quality.

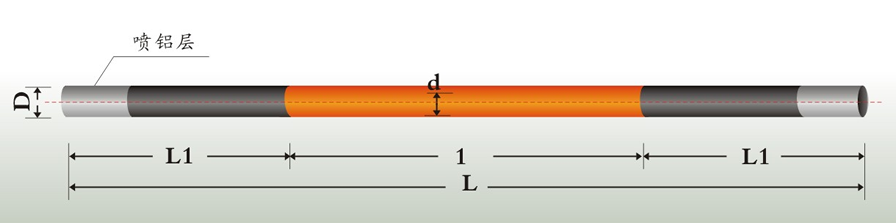

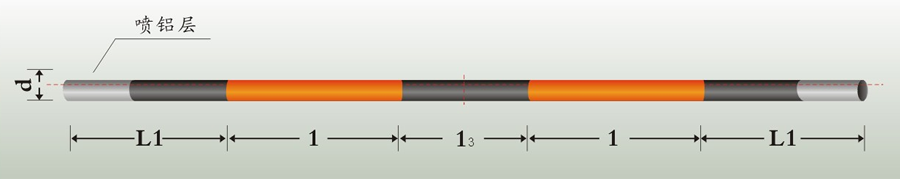

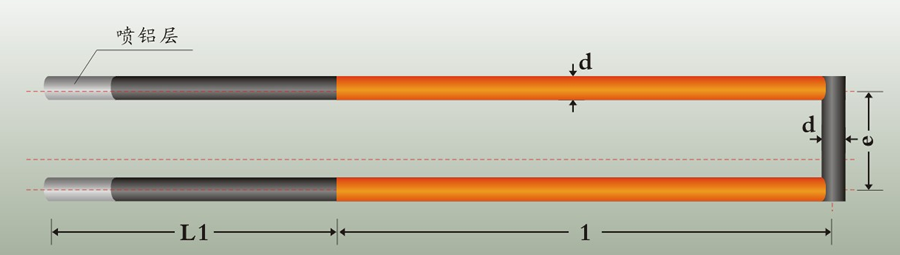

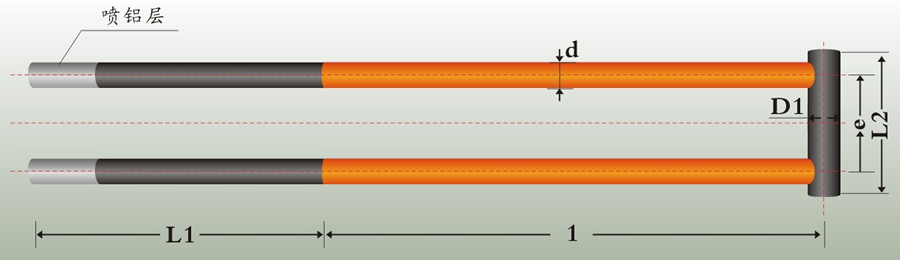

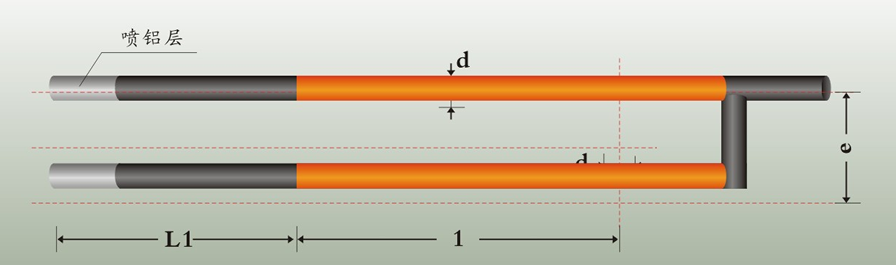

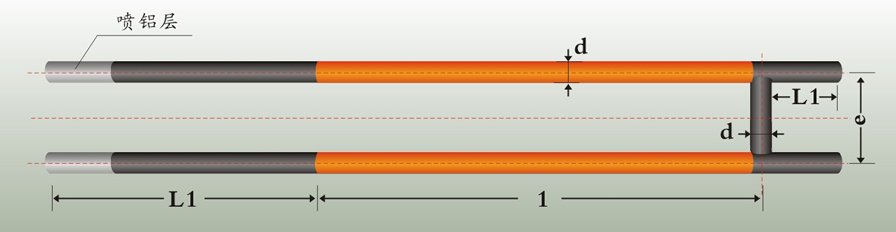

Universal silicon carbide rods are composed of one or more "heating parts" and "cold ends" that serve as connecting wires. They come in straight, U-shaped, and various special models to meet customers' needs from simple furnaces to complex electric furnaces.

The internal silicon carbide crystal structure is firm and uniform, heats up rapidly, and the highest surface temperature can reach 1450 degrees Celsius, which can exhibit excellent performance in various high-temperature processes.

The natural oxidation resistance and corrosion resistance of silicon carbide materials, combined with ultra-high temperature sintering technology, make silicon carbide rods have strong oxidation resistance and corrosion resistance even in the hot state. This ensures the stability and reliability of long-term use.

Silicon carbon rod electric heating elements have strong thermal radiation ability, rapid heating, and precise temperature control. This gives it significant advantages in processes that require fine temperature regulation.

Compared to metal electric heating elements and molybdenum disilicide electric heating elements, silicon carbon rod (SiC) heating elements have a smaller coefficient of thermal expansion, are not easily deformed at high temperatures, can be installed vertically or horizontally, and are suitable for various furnace types.

The design of silicon carbide rod products is flexible and can be processed into various shapes and specifications, such as straight, U-shaped, H-shaped, etc. Meanwhile, its installation method is simple and can be used in parallel, series, or mixed, greatly simplifying the installation and maintenance process.

According to customer requirements, the external dimensions of the universal silicon carbide rod are flexible and customizable. The resistance range can also be adjusted appropriately according to requirements.

1. The minimum diameter of standard products is 10 millimeters, and the maximum can reach 55 millimeters.

2. The length of the heating part can reach up to 3000 millimeters.

3. The length of the cold end can reach 1000 millimeters, and in special circumstances, it can be welded and extended.

Suitable for sintering ceramic resistors, ceramic capacitors, varistors, thermistors, and substrates, sintering and heat treatment of powder materials in various electronic industries, as well as annealing heat treatment of electronic components and materials.

Suitable for stainless steel brazing furnaces, aluminum alloy dissolution and casting insulation furnaces, and various metal carburizing, annealing, quenching, tempering and other heat treatment furnaces.

Continuous and intermittent powder metallurgy sintering furnaces.

Suitable for heating, insulation, and heat treatment in the glass and ceramic industries, as well as in industrial electric furnaces such as glass fiber, glass microbeads, and glass solar tubes.

Suitable for various chemical materials that require high-temperature sintering. It is widely used in drying furnaces, purification furnaces, coking furnaces, degreasing furnaces, and sintering furnaces.

Suitable for high-temperature experimental electric furnaces of various sizes and powers.