Contact Number : 029-83891808

Generally, traditional silicon carbide heating elements use recrystallization technology, and the density does not increase during the firing process. High performance silicon carbide (SiC) heating elements made by reaction sintering process have higher density and lower porosity, making them suitable for high-temperature environments with more stringent process requirements,

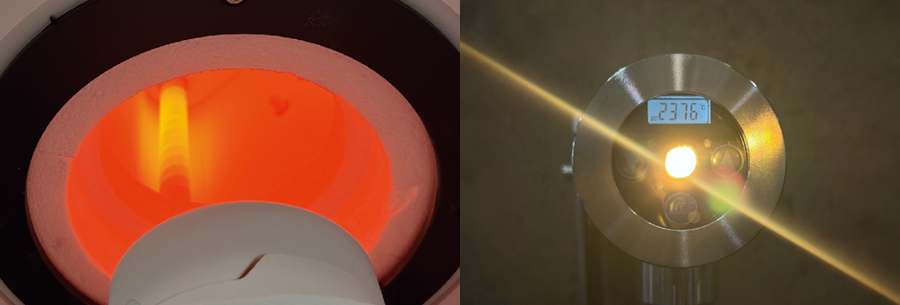

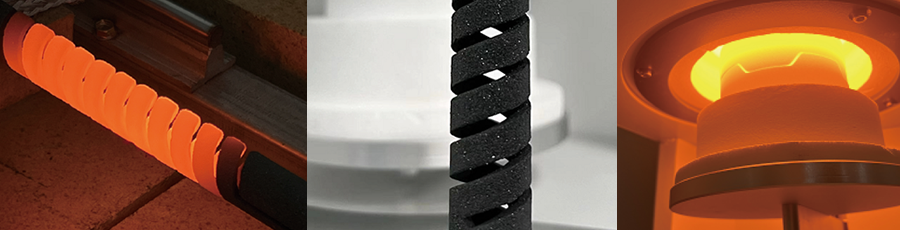

The Huaquan brand double threaded (SLW) silicon carbon rod is manufactured using industry-leading reaction sintering technology, with a maximum operating temperature of 1600 degrees Celsius, and can maintain excellent performance during continuous and intermittent heating processes.

The unique double helix heating structure has a higher electrical resistivity, combined with a smaller heating space, and the surface load is higher, resulting in a highly concentrated power output. Shorten heating time and improve production efficiency.

High usage temperature, fast heating, high thermal conductivity, and more uniform heating. It has excellent performance in both intermittent and continuous furnaces.

The porosity is only half of that of traditional recrystallization processes, and most of them are closed pores, which can reduce oxidation reactions in high-temperature environments and greatly extend the service life.

In high-temperature work, it does not decompose and produce harmful atmosphere, and does not pollute the burned materials.

Can be used in electric furnaces with a temperature range of 600 degrees Celsius to 1600 degrees Celsius, suitable for various sintering procedures such as standard and fast firing.

It does not require any support even in high temperature conditions and can be installed vertically or horizontally.

High temperature resistant ceramic accessories with integrated upgrade and optimization